Mr. Paige first had his attention directed to the typesetting problem about 1873, and in the next year he completed a composing machine which contained no provision for justification or distribution. He then invented and constructed an independent machine for distributing the type. In 1878 an arrangement was made with the Farnham Typesetting Company, of Hartford, Conn., for a distributing machine, and a combination was formed and a contract made looking to the introduction of machines using the Paige compositor and the Thompson distributor. About this time Mr. Paige invented his combined machine to contain the principal features of his compositor together with the leading features of the Thompson distributor, the type being taken from a galley and distributed into the bottom of the inclined channels, from which channels the type were delivered to an intermediate point in their length for purposes of composition. About 1881 a machine was completed for the double purpose of composition and distribution, but without provision for justification. A new machine was built by the Pratt & Whitney Company, and as early as July, 1887, type was automatically justified in the machine. The company passed through various vicissitudes, and the machine reached Chicago in 1892. Work was again started in February, 1894, and was pursued until August, 1894, when the first machine was completed and put in operation in the office of The Chicago Herald, and it is, claimed that wonderful results were obtained, but the matter had been delayed so long, and the art had advanced so much in the meantime, that it was not considered practical to build the machine.

Having given the history and romance of this remarkable patent, on our editorial page, we are enabled, through the courtesy of Mr. Philip T. Dodge, the President of the Linotype Company, who presented one machine to Cornell and the other to Columbia, to give a short account of the actual operation of this wonderful machine.

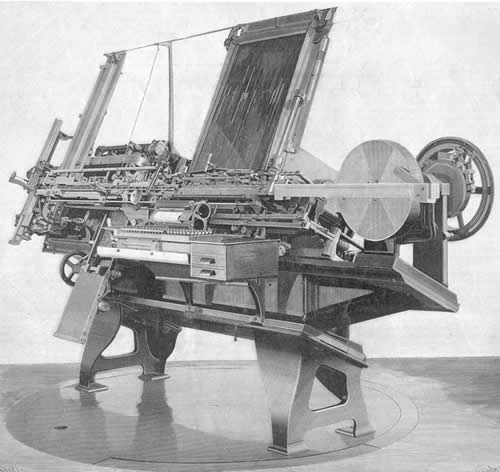

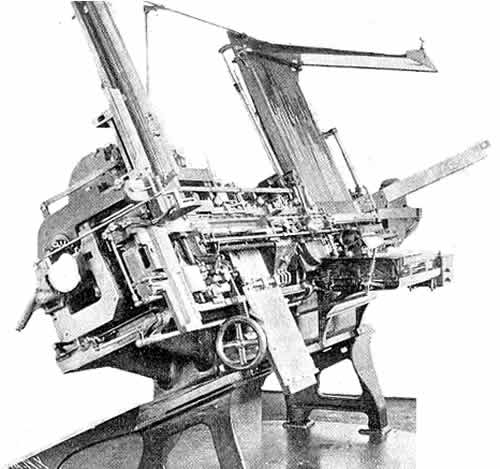

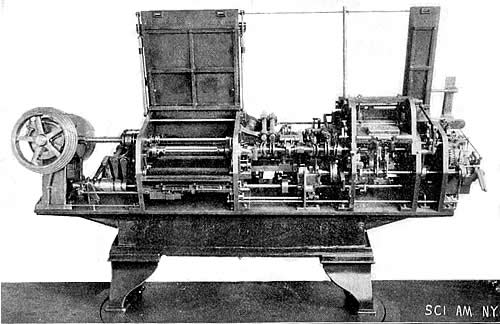

We will now briefly describe the Paige machine. Of course, only the merest outline can be given of the wonderful mechanism of this remarkable creation of the inventor. The machine was designed to use one size of type. The model machines constructed were for nonpareil type. The machine was arranged to distribute dead matter into both type and space cases automatically, to set matter from the type case by means of a keyboard, to automatically justify lines of matter by inserting between the words a space of a thickness predetermined by a series of word measurements, and to finally place the matter in galleys, solid, single or double-leaded, as desired, all of these operations being performed at the same time and in perfect harmony with each other. The type is contained in the vertical channels of the type case, which is slightly inclined to prevent the long columns of type failing to the front.

The setting is performed by a horizontal row of setter plungers, each plunger being in register with its particular channel and character. These plungers in action pass through the type channels about two inches above the lower end of type column, pushing type out from the column, upon a raceway in front.

The setting action, after the key has been pressed by the operator, is purely mechanical, being controlled by a time lock device. Depressing a key, operates through a horizontal wire to a vertical detented lever. This lever supports the rear end of an initial movement plunger, the front end of which engages with the setter plunger proper. The detented lever being pushed back by the key action, the initial plunger falls in front of it, and by the return of the detented lever is given a forward motion of one-quarter of an Inch. This forwards the setter plunger in exact time to become engaged by a revolving wing shaft, which completes the plunger's movement and sets the type out upon the raceway. A second wing shaft, revolving in opposite direction to the first, returns both the setter and initial plungers to position, the initial plunger being lifted, so that its rear end rests again upon the detented lever. The key is returned by the action which gives the initial movement to the plunger. One key, or as many as can be used in spelling from left to right, may be pressed at one and the same time.

The type set out upon the raceway by the plungers are collected at the left-hand side of the case by the type driver, which sweeps the entire length of the setter raceway. Here the word is completed, and measured by a mechanical device. A touch of the word key, and the word is forwarded to the word raceway. Each word is measured, and kept separated from the other. An indicator on the keyboard shows when the line is full. The line key is then pressed, which transfers the aggregate word measurement to the space-selecting device, pushes a pin, one of a circle of pins contained in a revolving disk, and returns the measuring device to its zero position, in time for the succeeding word.

The space case is located at the left end of the machine, and arranged in the same general manner as the type case.

The line of separated words traverses the word raceway until the space case is reached. Each word is then carried across the front of this case by a long movement of the comb or conveyer. It is while the comb is returning for another word that the space is set out from the case; the next word forwarded, carries this space with it into the line. This continues until the line is formed, perfectly justified, upon a slide located over the setter galley. Concurrent with the assembling of the last word into the line, the pin, previously set by the line key action, engages to retract the slide under the line, and push the line down into the setter galley, single or double leads being inserted as desired. This continues until the galley is filled, indicated by an alarm, or until copy is exhausted.

The space case holds spaces of eleven different sizes. To determine the thickness of space necessary to justify a line, the measure of each word, as it is being set, is successively recorded upon a sliding bar. With the last word of the line measured, the bar has moved to the aggregate of the words contained in the line. Concurrent with each word set, pin blocks moving in an endless chain, and containing eleven sliding pins each, have been advanced step by step, so that when the line is finished a block for each word it contains has been moved into a position to engage with a plate, having raised blocks arranged in combination upon its surface. Twelve of these combination plates are contained in a horizontal grooved box. The plate to be advanced from this box to a position under the pin blocks is determined by the number of words contained in the line. The distance which it must be advanced that the proper combination of blocks may engage with, and set the pins in pin-blocks, Is determined by the measure of the line recorded upon the sliding bar. The blocks and plate being in position, a slight vertical movement engages the two. Pins coming in contact with combination blocks are raised above the others. These blocks now move in unison with the line they represent, and reach the space case together, the words in front of the case, the pin-blocks at the rear. The space setter plungers are operated by a row of eleven vertical levers, engaging at the bottom with the plungers, and at the top in register with the pins in pin-blocks. The upper end of levers are made with a point projecting backward at right angle to the vertical, and raised slightly above the top of pins in normal position. As the first word of line is carried past the space case, the first block is moved in register with the vertical levers. A rocking motion carries the top of levers backward, engaging them with any pins previously raised by combination blocks. Any lever so arrested in its backward motion imparts an initial movement to its particular setter plunger, which sets the space out upon the raceway, to be carried along by the succeeding word into the line. Each block in turn is brought into register with the levers until the spaces are set and the line Justified.

Dead matter, with leads and rules extracted, is placed in galley for distribution. A vertical movement registers the top line of type with a horizontal blade, which forwards it into a raceway. A longitudinal slide presses the end type into the cut-off, which separates it from the line, and raises it to the level of the distributor raceway, upon which it is pushed by a plunger, to be forwarded by a comb movement. The cut-off operates continuously, separating one type at a time from the line. All characters are forwarded to the right, to be distributed Into the type case, while all spaces move to the left, to be distributed into the space case. A system of notches on edge of type, arranged in combination with a selecting device, enables the type to be distributed into their respective channels. The distribution is made into the bottom of the case, the column of type rising as each type is inserted. To prevent this interfering with the setting, which is performed at a point about two inches above, the distribution and setting are arranged to take place on different portions of the revolution of the machine.

Related Twain - Paige news stories:

"Mark Twain, James W. Paige and the Paige Typesetter"

- Special Feature

"James W. Paige and the Jilted Actress"

The New York Times,

March 30, 1892

Chicago Daily Tribune, May

7, 1892

The New York Times, November 13, 1927

The New York Times, October 1, 1940